Explore the HES3D-70 Concealed Hinge

Compact and versatile, the HES3D-70 is designed for smaller doors and cabinetry where space constraints require a low-profile yet high-performing hinge solution. With a shallow bore depth and minimum door thickness of just 19mm, it's easy to install while maintaining a sleek, concealed finish. Ideal for premium residential or light commercial interiors, the hinge features a split design for separate door and jamb mounting, along with 3-way post-installation adjustability for vertical, horizontal, and depth fine-tuning. Despite its compact size, it offers impressive load capacity and smooth operation, tested to 50,000 cycles.

-

Hinge can be split into the door side and the jamb side

-

3-way adjustment function allows vertical, horizontal, and depth adjustment after the hinge is installed

-

Small bore depth, easy to cut out the door and jamb

Specifications:

-

Opening Angle: 180°

-

Max Door Dimensions: Width 600mm, Height 1200mm

-

Door Thickness: 19mm minimum

-

Weight Capacity: 9kg with 2 hinges, 16kg with 3 hinges

-

Tested Durability: 50,000 open/close cycles

-

Mounting Style: Concealed, split-type with wide-throw design

Available Finishes:

Installation Instructions

The HES3D-70 offers three-axis post-installation adjustment, allowing for precise alignment without removing the hinge from the door or jamb.

-

Horizontal Adjustment: ±1.5 mm

(Screws located on the door side, two locations) -

Vertical Adjustment: ±1.5 mm

(Screws located on the jamb side, two locations) -

Depth Adjustment: ±1 mm

(Screws located on the jamb side, central positions)

All adjustments can be made with a standard screwdriver. Always ensure that all fixing screws are fully tightened after final alignment to maintain hinge integrity and performance.

The locus chart defines the movement arc of the hinge and highlights the required installation tolerances:

-

The hinge provides a 180° opening arc with minimal clearance.

-

The reference surface of the door must align with the reference surface of the side panel (jamb).

-

A minimal clearance of 8 mm is designed into the pivot area to ensure smooth, obstruction-free operation.

Correct alignment of reference surfaces is critical to avoid binding or mechanical interference during door movement.

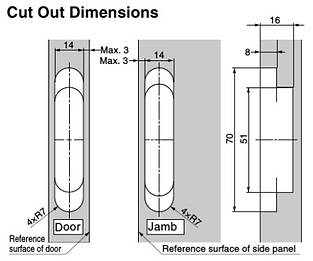

Accurate cutouts are essential for correct installation and hinge function. The door and jamb cutouts are identical and must be aligned to their respective reference surfaces.

Door & Jamb Cut-Out:

-

Height: 70 mm

-

Width: 14 mm

-

Corner Radius: R7

-

Depth: 16 mm

-

Setback: Max. 3 mm from the door or jamb reference surface

Ensure all cutouts are clean and square for a flush and concealed fit.

CONTACT

Inquiries

For any inquiries, questions or commendations, please call: 08 9333 4999 or fill out the contact form

Navigate

Office & Warehouse

274 Welshpool Road Welshpool, WA 6106

Tel: 08 9333 4999

28 Indian Drive Keysborough, VIC 3173

Tel: 03 9706 8400

© 2025 Nessco Trade Supplies